As an experienced roofing professional, I’ve seen the incredible impact that roof coatings can have on the longevity, efficiency, and overall performance of commercial buildings. Whether you manage a sprawling office complex, a bustling retail center, or a state-of-the-art industrial facility, the right roof coating can make all the difference. But when it comes to applying these coatings, you have two primary options: DIY application or professional spraying.

In this comprehensive guide, I’ll dive deep into the world of commercial roof coatings, exploring the key differences between DIY and professional application, the benefits and drawbacks of each approach, and the critical factors to consider when making this important decision. By the end, you’ll have a clear understanding of the best path forward for your commercial property.

Roof Coating Basics

Before we delve into the specifics of DIY vs. professional application, let’s start with a quick overview of the different types of roof coatings and the advantages they offer.

Types of Roof Coatings

The three most common types of commercial roof coatings are:

-

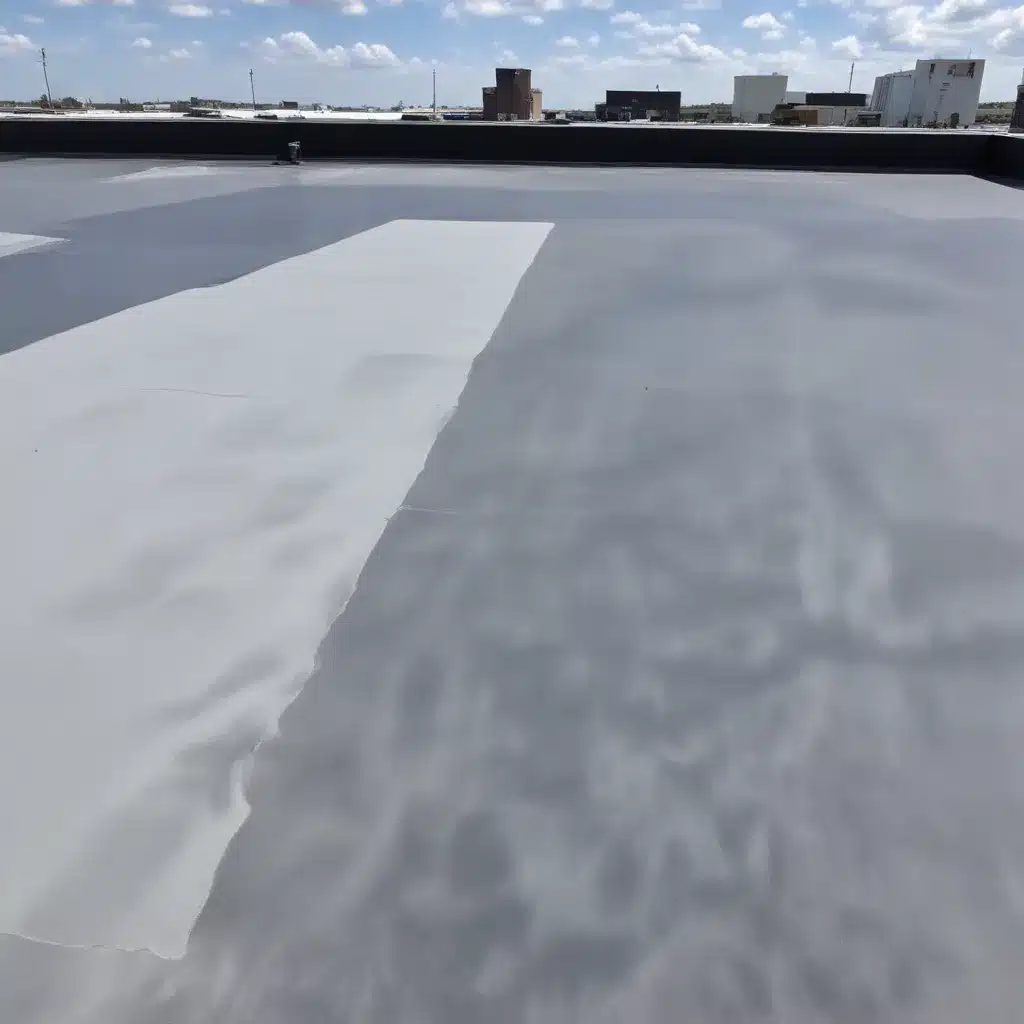

Acrylic Coatings: These water-based coatings provide excellent UV protection, reflectivity, and waterproofing. They’re a popular choice for flat or low-slope roofs.

-

Silicone Coatings: Offering superior weatherproofing and durability, silicone coatings are often used on metal roofs, aged asphalt, and other challenging surfaces.

-

Polyurethane Coatings: Known for their flexibility and chemical resistance, polyurethane coatings are well-suited for roofs that experience a lot of foot traffic or movement.

Benefits of Roof Coatings

Regardless of the specific type, commercial roof coatings offer a wide range of benefits that can significantly improve the performance and longevity of your building’s roof:

- Improved Insulation: Roof coatings can enhance a roof’s insulation capabilities, helping to reduce energy costs and improve indoor climate control.

- UV Protection: Many coatings contain specialized pigments that reflect harmful UV rays, shielding the roof membrane from premature degradation.

- Waterproofing: A high-quality roof coating creates a seamless, waterproof barrier, preventing leaks and water infiltration.

- Extended Roof Lifespan: By protecting the roof from the elements and preventing damage, coatings can extend the useful life of the roof system by 10-20 years or more.

Now that we’ve covered the basics, let’s dive into the key differences between DIY and professional roof coating application.

DIY Roof Coating Application

For some commercial property owners, the prospect of tackling a roof coating project themselves can be tempting. After all, it may seem like a straightforward process that can save you a significant amount of money. However, before you grab a bucket of coating and a roller, it’s essential to understand the unique challenges and considerations of a DIY approach.

Surface Preparation

Proper surface preparation is crucial for the success of any roof coating application, whether DIY or professional. This typically involves:

- Cleaning: Thoroughly cleaning the roof surface to remove dirt, debris, and any existing coating or sealant residue.

- Repairs: Identifying and repairing any cracks, holes, or other damage to the roof membrane before applying the coating.

- Primer Application: Applying a compatible primer to the surface, as recommended by the coating manufacturer.

Skipping or cutting corners on these essential preparatory steps can lead to adhesion issues, premature failure, and costly repairs down the line.

Coating Application Techniques

When it comes to actually applying the roof coating, DIY-ers have a few options:

- Roller: Applying the coating with a high-quality roller can be an effective and relatively straightforward method, but it requires careful attention to ensure even coverage.

- Brush: For hard-to-reach areas or detailed work, a brush can be a useful tool. However, it’s generally more time-consuming and labor-intensive than other application methods.

- Airless Sprayer: Using an airless sprayer can provide a fast, efficient, and consistent coating application. But it requires specialized equipment and training to operate safely and effectively.

Considerations for DIY

While the DIY approach may seem like an attractive option, there are several important factors to consider:

- Safety: Working on a roof can be inherently dangerous, and proper safety precautions, such as fall protection and hazardous material handling, are essential.

- Time Commitment: Applying a roof coating can be a labor-intensive process, especially for larger commercial buildings. DIY-ers need to be prepared to invest significant time and effort.

- Equipment Required: Obtaining the necessary equipment, such as sprayers, rollers, and accessories, can add to the overall cost and complexity of the project.

- Potential Issues: Without proper training and experience, DIY-ers run the risk of encountering application problems, such as uneven coverage, adhesion failures, or premature degradation of the coating.

For many commercial property owners, the risks and challenges of a DIY roof coating application may outweigh the potential cost savings. In these cases, partnering with a professional roofing contractor may be the best path forward.

Professional Roof Coating Spraying

When it comes to commercial roof coatings, professional application by a trained and experienced roofing contractor offers a number of distinct advantages over the DIY approach.

Specialized Equipment

Applying a roof coating, especially on a large commercial building, requires specialized equipment that goes beyond what the average DIY-er would have access to. This includes:

- Airless Sprayers: High-powered airless sprayers allow for a fast, efficient, and consistent application of the coating material.

- Compressors: Powerful air compressors provide the necessary air pressure to operate the sprayers and ensure proper atomization of the coating.

- Hoses and Accessories: Professional roofers utilize high-quality hoses, tips, and other accessories to ensure a seamless and effective application process.

Expertise and Training

In addition to the specialized equipment, professional roofing contractors bring a wealth of expertise and training to the table. This includes:

- Application Techniques: Experienced roofers know how to apply the coating material in a way that ensures proper coverage, adhesion, and consistency.

- Safety Protocols: Professional crews are trained in the safe handling of hazardous materials and the implementation of OSHA-compliant safety measures.

- Warranty Coverage: Many reputable roofing companies offer comprehensive warranties on their roof coating services, providing an additional layer of protection and peace of mind.

Advantages of Professional Application

The combination of specialized equipment and expert knowledge delivers several key advantages when it comes to professional roof coating application:

- Faster Process: With the right tools and techniques, professional crews can complete the coating application much more quickly than a DIY-er.

- Consistent, High-Quality Results: Experienced roofers know how to achieve a seamless, uniform coating that maximizes the material’s performance and longevity.

- Warranty Coverage: The warranty provided by a professional roofing contractor can help safeguard your investment and provide long-term protection for your commercial roof.

While the upfront cost of professional roof coating services may be higher than a DIY project, the long-term benefits and potential cost savings often make it a worthwhile investment for many commercial property owners.

Maintenance and Longevity

Regardless of whether you choose a DIY or professional approach, maintaining your commercial roof coating and understanding its expected lifespan are crucial for maximizing its performance and value.

Periodic Inspections

Regular inspections of your roof coating are essential for identifying any signs of wear, tear, or potential problems. During these inspections, you (or your roofing contractor) should:

- Carefully examine the coating for cracks, blisters, or other visible damage.

- Check for areas where the coating may be wearing thin or peeling.

- Identify and address any underlying roof issues that could compromise the coating’s performance.

Reapplication Needs

Most commercial roof coatings have a typical lifespan of 10-15 years, depending on the specific product, the quality of the initial application, and the environmental conditions the roof is exposed to. As the coating begins to degrade, it’s important to be on the lookout for signs that it’s time for a reapplication, such as:

- Significant fading or discoloration of the coating.

- Noticeable loss of reflectivity or waterproofing capabilities.

- Extensive cracking, peeling, or other visible damage.

Extending Roof Lifespan

By properly maintaining your commercial roof coating through regular inspections, timely repairs, and eventual reapplication, you can significantly extend the useful life of your roof system. This not only saves you money on premature roof replacement but also helps to improve the overall energy efficiency and sustainability of your building.

Cost Considerations

When it comes to commercial roof coatings, the cost factor is often a significant consideration for property owners and facility managers. Let’s take a closer look at the various cost-related aspects of DIY vs. professional application.

Material Costs

The cost of the coating material itself can vary widely depending on the type of coating, the quantity required, and any additional accessories or primers needed. In general, higher-quality coatings will come with a higher price tag, but may offer better long-term performance and value.

Labor Costs

The labor costs associated with a roof coating project can be a significant differentiator between DIY and professional application. While a DIY approach may seem like a more budget-friendly option upfront, the time and effort required can quickly add up, especially for larger commercial buildings. In contrast, professional roofing contractors often have the expertise and efficiency to complete the job in a fraction of the time, potentially offsetting the higher labor costs.

Long-term Savings

When evaluating the overall cost of a commercial roof coating project, it’s crucial to consider the long-term savings and benefits. A high-quality, professionally applied coating can:

- Enhance the building’s energy efficiency, leading to reduced HVAC and energy costs.

- Extend the lifespan of the roof system, potentially delaying the need for a costly roof replacement.

- Provide comprehensive warranty coverage, protecting your investment and giving you peace of mind.

By taking a holistic view of the cost factors, many commercial property owners find that partnering with a professional roofing contractor is the most cost-effective approach in the long run.

Eco-Friendly Roof Coatings

As environmental sustainability becomes an increasingly important consideration for commercial buildings, eco-friendly roof coatings have emerged as a popular and responsible choice. These specialized coatings offer a range of benefits that can contribute to a building’s overall green initiatives.

Environmentally-Friendly Formulas

Many modern roof coating products are formulated with low-VOC (volatile organic compound) content and sustainable materials, making them a more environmentally-friendly option. These coatings are designed to minimize their impact on indoor air quality and reduce their carbon footprint.

Energy-Saving Benefits

Roof coatings with reflective properties can significantly improve a building’s energy efficiency by reducing heat absorption and the associated cooling load. This, in turn, leads to lower energy consumption and a smaller environmental impact.

Contribution to Green Building

The use of eco-friendly roof coatings can be an important component of a commercial building’s green certification, such as LEED (Leadership in Energy and Environmental Design) or other sustainability programs. By selecting and properly applying these coatings, property owners and facility managers can demonstrate their commitment to environmental responsibility and sustainable building practices.

Whether you choose a DIY or professional approach, incorporating eco-friendly roof coatings into your commercial building’s maintenance and upgrade strategy can be a smart and forward-thinking decision that benefits both your bottom line and the planet.

As a seasoned roofing professional, I hope this comprehensive guide has provided you with a clear understanding of the key differences between DIY and professional roof coating application, as well as the critical factors to consider when making this important decision for your commercial property. By weighing the advantages, costs, and long-term implications of each approach, you can make an informed choice that best aligns with your building’s needs, your budget, and your commitment to sustainability. For more information or to connect with a reliable roofing contractor in the El Cajon area, please visit https://rooferselcajon.com/. Together, we can ensure your commercial roof performs at its best for years to come.